Location:HomePage > Products > Semi-continuous tri-chambers magnetic field vacuum > Semi-continuous tri-chambers magnetic field vacuum

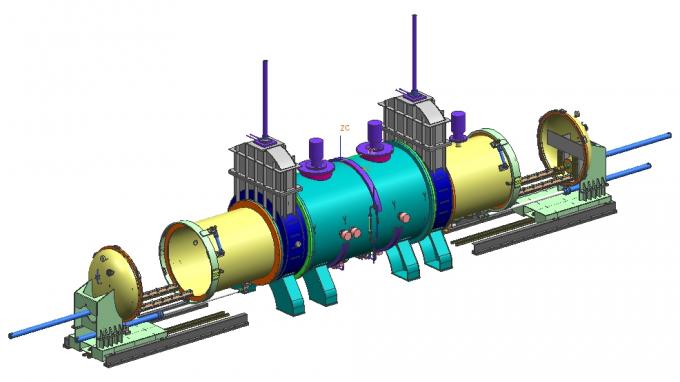

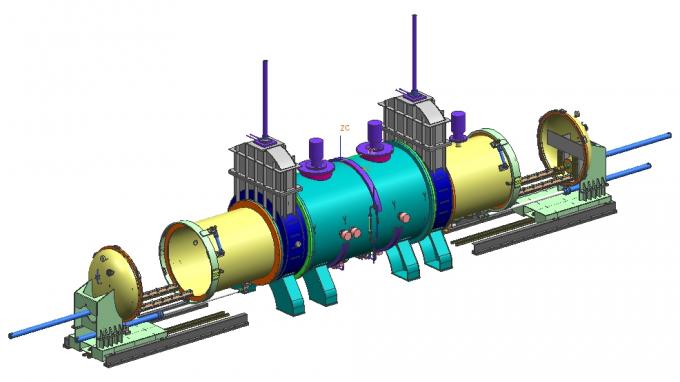

Location:HomePage > Products > Semi-continuous tri-chambers magnetic field vacuum > Semi-continuous tri-chambers magnetic field vacuum Semi-continuous tri-chambers magnetic field vacuum

Introduction of Equipment Structure

This production line is made up of cut-to-length cross-cut shears, box-type curing furnace with roller transmission, semi-continuous tri-chambers magnetic field heat-treatment furnace and electric control system, etc.

Application:

This production line is mainly used for annealing magnetizing heat treatment and curing of special metal material.

Equipment features:

1. The cut-to-length cross-cut shears are used in constant length cutting, scale piling and weighing of steel belt laminated plate: when every part of the transmission system is in normal operation, and the hydraulic pressure is normal, filling-reeling can be started then; the material is put manually on the expansion-shrinking roller which will expand and shrink the material; the motor controls the unreeling; interlayer center position device centers; feeding machine feeds materials to the length, hydraulic punching by the electric control cross-cut shear, weighed on the weighing platform, positioning weighing piling by the weighing piling platform.

2. Box-type curing furnace with roller transmission is mainly used in solidification treatment of workpiece, and it is made up of four parts such as the furnace body, lifting device, external turnover platform and peripheral raceway.

3. The semi-continuous tri-chambers magnetic field heat-treatment furnace is mainly used for annealingmagnetizing treatment of special metal material, and is made up of three chambers : preparation room, vacuum container and cooling chamber. It includes furnace body, vacuum system, charging magnetic field, gas distribution system, hydraulic system, circulating water system, material rest operation process, and electric temperature control system, etc. The system is operated in front of the furnace, and the monitoring equipment is in operation state. It is also made up of super place system equipped with configuration process control software, digital display temperature controller, thyristor power control unit and electric control system, etc. The movements are controlled by PLC orderly, to guarantee the furnace door switch, furnace door turnover, magnetizing location, and operation of hydraulic cylinder, air cylinder and circulating motor.

|

||||

|